direct drive motor applications

Nimble Electrics BLDC Torque Motors offers various methods of heat dissipation such as natural cooling forced air cooling or forced water. Servo drives designed for torque frameless or direct drive motors require high switching frequencies in the range of 40 to 125 kHz depending on the motor electrical time constant.

Electrical Motor Controls D F Liquidators

The most widely used motor type for a direct drive application is typically a high pole count permanent magnet synchronous motor AKA.

. Testing and inspection devices. 2 hours agodrylin D2 motor control system for stepper DC and ECBLDC motors. 115 04 9 W.

B1020N 10mm Brushless DC Motor Diameter10mm Length20mm Voltage37v 74v Power115W Speed39300rpm Applications Medical EquipmentIndustrial Automation Options Lead wires lengthShaft. Free fast and easy way find a job of 1779000 postings in Piscataway NJ and other big cities in USA. Ad Cutting holemaking shaping tools.

The benefits of high-pole-count designs vary depending on who you ask. 4300 rpm - 39300 rpm. In the most common motor-driven systems the motor is coupled to the load being moved by a mechanical transmission element a belt chain rack and pinion ball or lead screw or even simply a gearbox.

Temperature measurement in direct drive motors. They offer an alternative to pneumatic and ball screw actuators with both high speed and high thrust force capabilities. Direct drive motors and motion systems.

Lesson Direct is Your Online Solution For Electric Motors Controls. For direct drive torque motors inertia is low which makes the motors very suitable for high speed acceleration applications with fast starts and. DDR Direct Drive Rotary motors are popular in many applications because they offer unique differences for positioning speed torque and mechanical fitment.

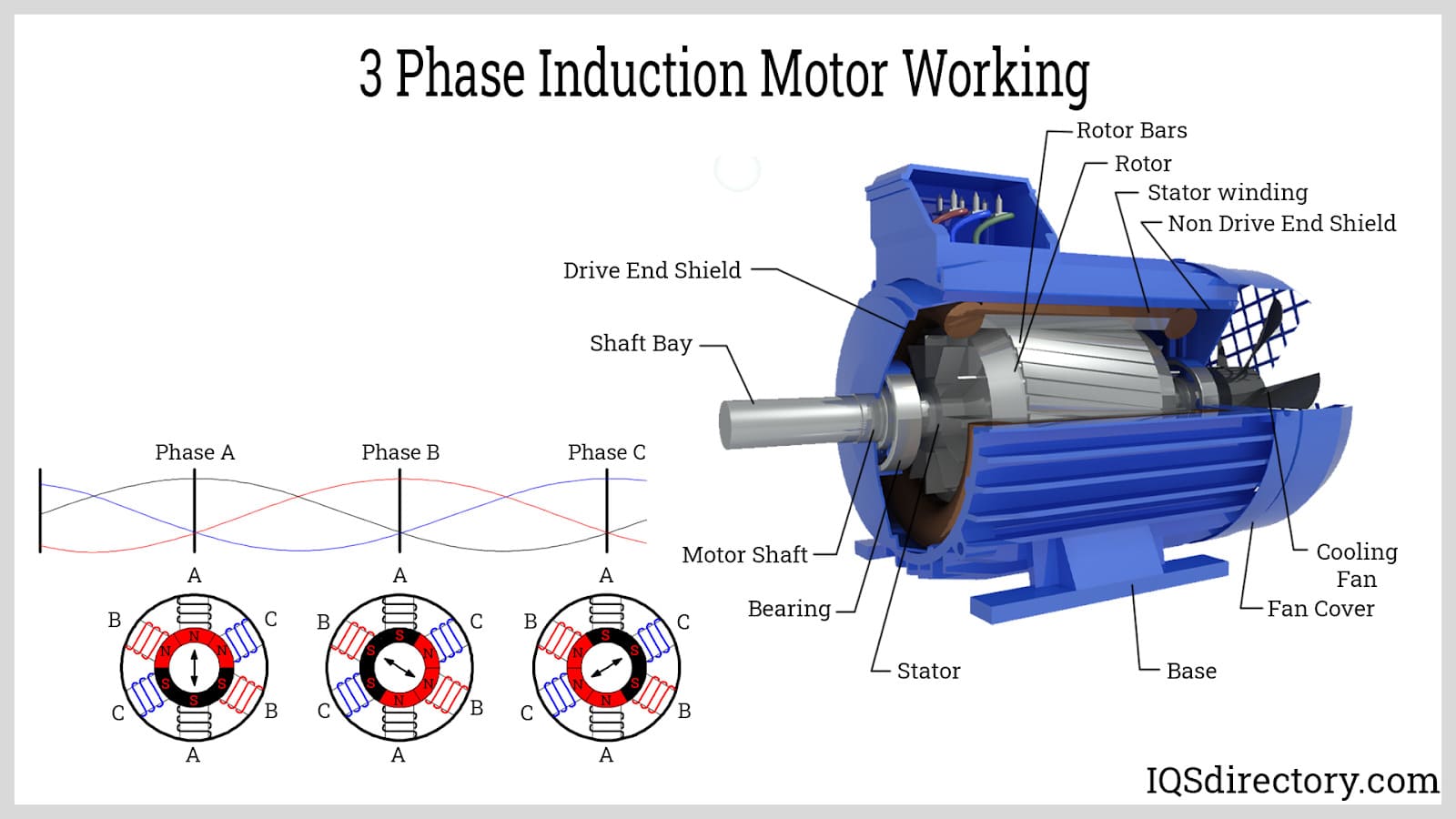

Standard off-the-shelf motors typically feature two to four poles although versions featuring as many as 10 poles are available. Direct drive motor applications have relatively low speed and the mechanism is designed for flange mount instead of shaft mount. PWM 21 inspection device.

This means that a high torque is required to accelerate the motor. But some linear and rotary motion systems do away with mechanical. This is achieved by using transistor technology with low switching losses and perfectly tuned gate drivers in order to control the heat generated by the servo drive.

OD34-38mm 15-24V DC Motors Gearbox Gear head We offer customized solutions. It helps to eliminate the need. A direct-drive motor can be directly coupled to the load for high torque and low-speed applications such as washing machines.

Full-time temporary and part-time jobs. The salary range for a Direct Care Worker in Piscataway NJ is from 21000 to 37000 per year or 10 to 18 per hour. These BLDC torque motors provide better torque density as well as high peak torque making them ideal for applications requiring minimal size weight and power yet offering sharp response times.

00001 Nm - 00112 Nm. 2 Million Customers Choose Zoro. In contrast some direct-drive motors can feature 46 poles or more see figure 2.

Its magnetic and mechanical configuration provides high torque and a high ratio of electrical drive frequency to mechanical speed. PWT 101 testing device. Furthermore geared motors have a lower torque to inertia ratio.

No software installation or app required. Provide support transportation and assistance for each individual to enable herhim to complete daily routines in a safe healthy productive and dignified manner. They offer low cost high speed small envelope and are easily adaptable to gearboxes and actuators.

Another good application is to drive the spool in a winding application or rolls for printing or cutting. A wide range of automation tasks by simple parameterisation no programming necessary. Testing and inspection devices.

Ad Leeson Electric Motors Drives Controls. Therefore direct drive technology achieves a very high lifetime. Ad D34-38mm 15-24V Precision plastic gears motormini gearmotors and custom-made service.

To View Apply for jobs on this site that accept applications from your location or country tap the. The most common application is a rotary table or rotary indexer. A direct drive system allows the load to be attached directly to the motor.

Sealed linear encoders with their resistance to dust chips and cooling lubricant are ideal for machine tools. Modular solutions offer nearly unlimited flexiblity for installation in a wide variety of applications. Industries Applications.

Conventional rotary servo motors are typically the logical choice for most applications. Use with PC tablet or smart phone. Direct drive motor benefits and applications Rotary direct drive torque motors are often used in robot applications.

Search and apply for the latest Direct care support jobs in Piscataway NJ. Direct Support to consumers whether in an In-Home or Group Home setting. Exposed linear encoders are available for direct drive motors especially in measuring equipment.

Testing of machine tools. Brushless DC that has a large diameter and short axial length. For single axes line flat linear and room linear robots and delta robots.

Direct-drive motors tend to use very high numbers of poles. Tubular direct drive linear motors can be iron core or ironless types.

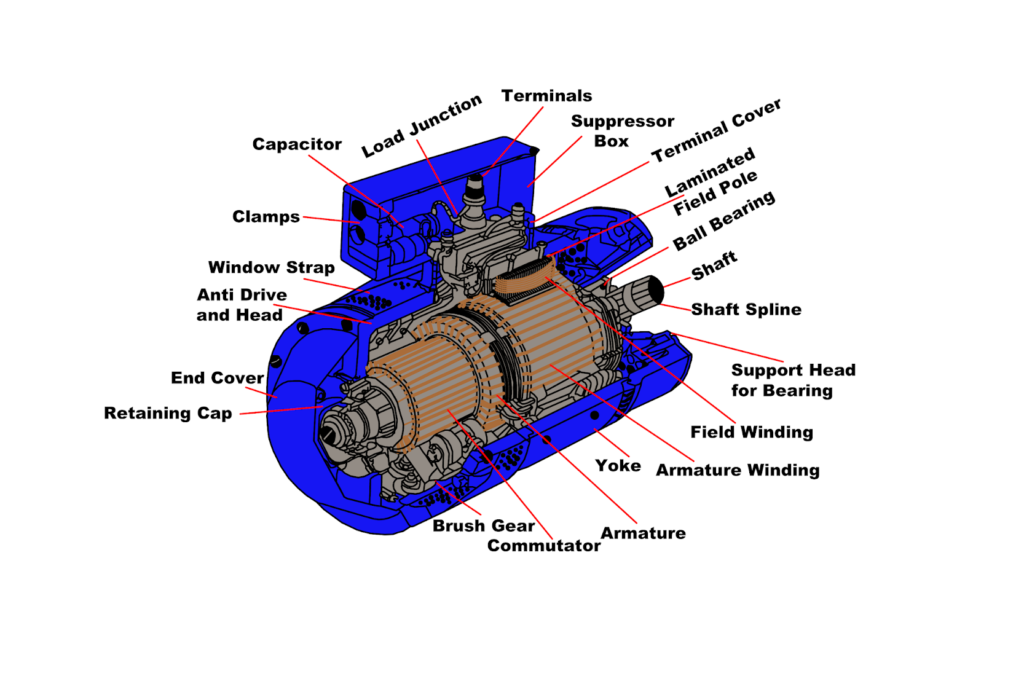

Types Of Electric Motors Their Working Applications Pdf

Direct Drive In Wheel Motors Elaphe

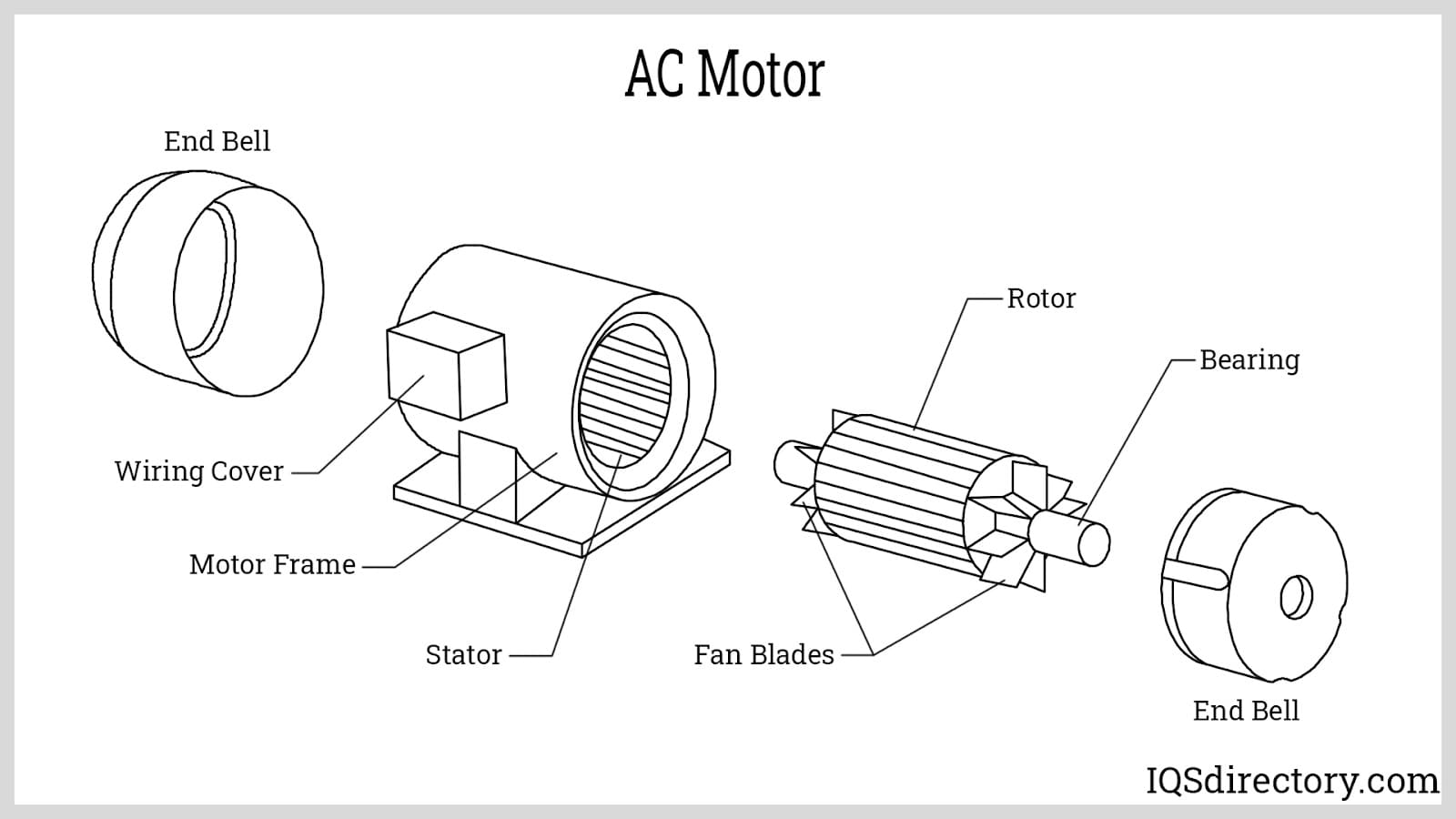

Electric Motors Types Applications Construction And Benefits

Electric Motors Types Applications Construction And Benefits

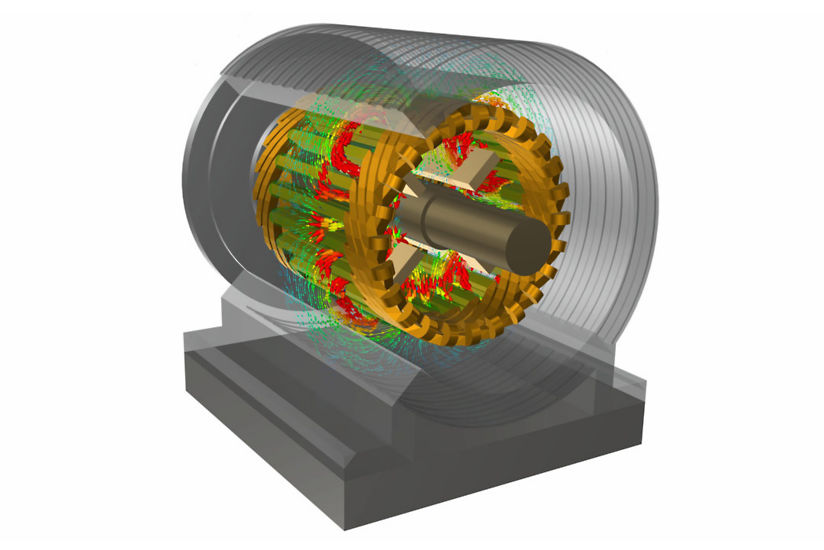

Electric Motor Design Software Ansys

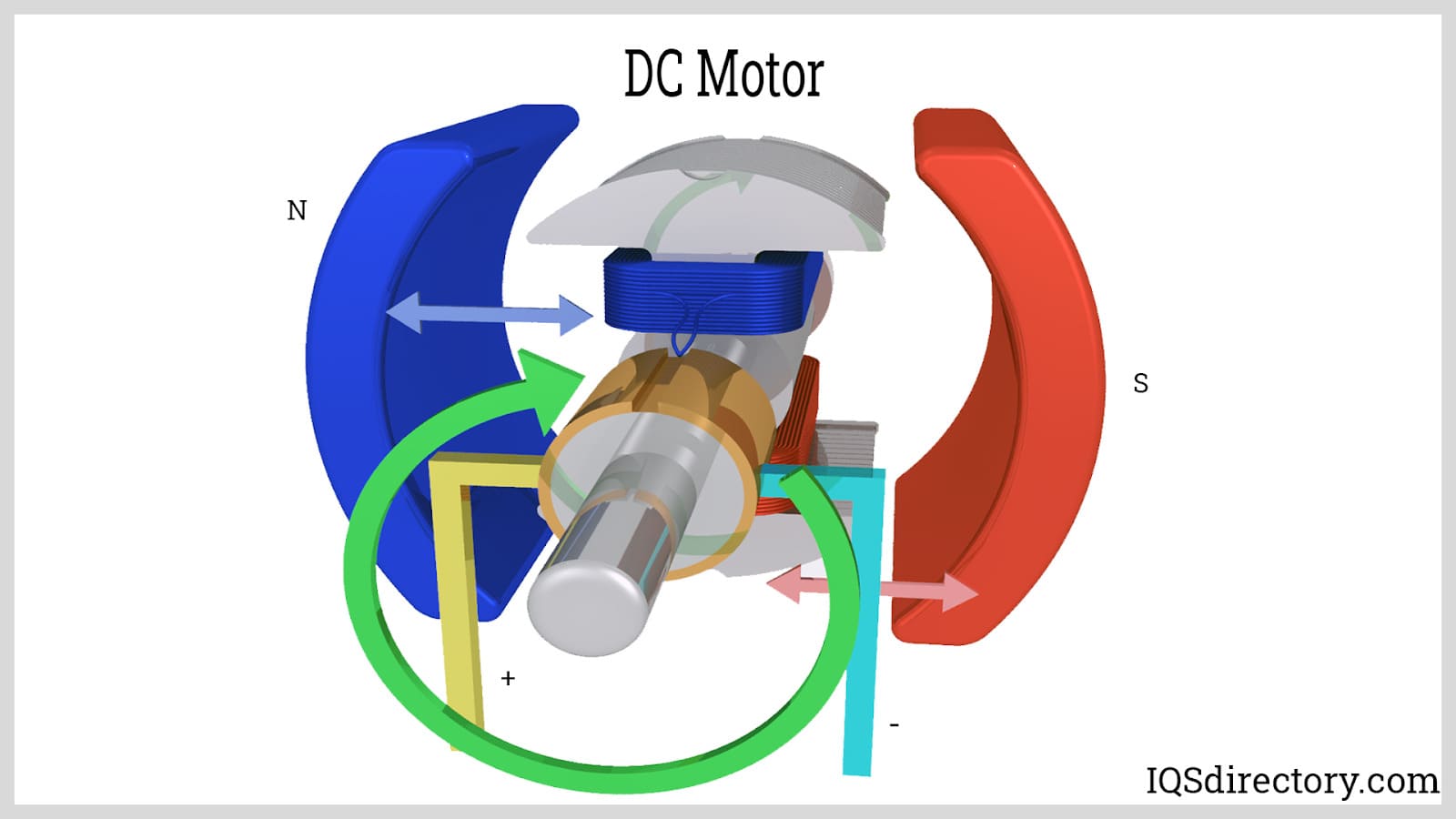

Permanent Magnet Dc Motor Pmdc Motor How Do They Work Electrical4u

Bowden Vs Direct Drive Comparing 3d Printer Configurations

Dc Motor Applications An In Depth Blog Robu In

Electric Motors Types Applications Construction And Benefits

Electric Motors Types Applications Construction And Benefits

What Is Motor Definition Types Working Principle Applications The Engineering Knowledge

What Is A Servo Motor And How It Works Realpars

What Is Brushless Dc Motor Bldc Construction Working Motor Generator Electrical Motors Motor

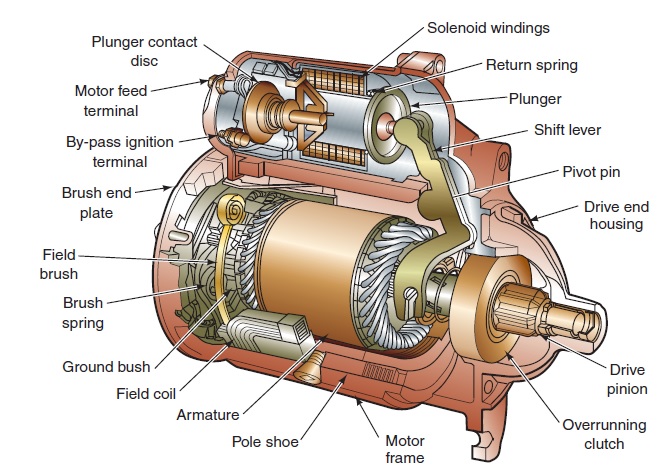

8 Different Dc Motor Parts Structure Design And Advantages Pdf Linquip

About Shaft Couplings Nbk The Motion Control Components

Bowden Vs Direct Drive Comparing 3d Printer Configurations

Dc Motors And Stepper Motors Used As Actuators